Business & people

Milacron Reports Solid Growth

작성자 : Aeyoung Park

2018-07-30 |

조회 : 4869

- Milacron Holdings Corp. reported a solid second quarter with record sales, plus gains in new orders and profit

| ▲ Micron's Tom Goeke addresses the media at the company exhibit at NPE2018. |

And for any observers wondering about the impact of tariffs on the largest U.S. plastics machinery company, CEO Tom Goeke said U.S. tariffs on steel and aluminum, and components from China, amount to only 0.8 percent of sales.

Goeke credited the results to continued growth in Milacron's consumables business as well as the high-growth regions of China and India, where the company has manufacturing operations.

In a July 26 conference call, Goeke told financial analysts that all the racket about tariffs did impact orders, but things are returning to normal.

"What we did see at the announcement of the tariffs up until maybe two weeks ago was a lot of discussion of what's going to happen about placing orders. And I'd say in the last two or three weeks, it's resumed a very good clip," he said.

Goeke addressed the tariff issue both in his prepared remarks and answering questions from analysts. He said Milacron can take four actions to mitigate higher costs from the tariffs. One is price increases, which he said the company has already implemented in some cases.

"We've had some pretty good success moving price in the first two quarters and we seem to be going pretty well in the third quarter," he said.

The second area is negotiating prices with vendors. He said Milacron can source some subassemblies from India and countries in Southeast Asia where the tariffs don't apply.

Goeke said Milacron also is seeking exceptions to some of the tariffs. Before a May 15 government hearing on the tariffs, Goeke told the U.S. Trade Representative that the China tariffs should not be enacted on Chinese-made components that it relies on heavily, although Milacron did favor keeping tariffs on finished plastics machinery from China.

And in the second-quarter financial results, Milacron said the largest exposure to tariffs comes from its machinery segment.

The fourth tariff mitigation action would be modifying its own manufacturing supply chain, although Goeke said: "At this point we have not considered manufacturing, but our manufacturing footprint provides opportunities if changes are necessary."

Financially, Milacron did well in the first half of 2018.

"Milacron continues momentum from the first quarter and delivered another solid performance" in the second quarter, Goeke said. Consumable items — including hot runners, DME mold components, aftermarket parts and service, and fluids for metalworking — increased by 9 percent from the first quarter.

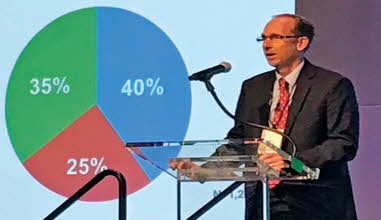

Consumables now account for 68 percent of sales.

Overall second-quarter sales were $328.1 million, an increase of 6.1 percent from $309.2 million in the second quarter of 2017, or 3.7 when adjusted for currency fluctuations. New orders were up 2.2 percent, to $334.9 million, or stayed flat when figuring in currency.

Milacron, which is traded on the New York Stock Exchange, reported a big jump in profit. Net profit was $14.9 million, up 32 percent vs. 2017 second quarter profit of $10.1 million. For the first half, net profit was $20.8 million compared with a loss of $14.5 million in the prior-year first half.

Looking at business segments, plastics processing machinery — formally named Advanced Plastics Processing Technologies — second-quarter sales increased 2.2 percent over the second quarter of 2017, hitting $170.4 million.

Machinery growth so far this year is coming from double-digit increase in India, partially offset by a decline in Europe, Milacron said.

Aftermarket growth was 7 percent in the second quarter. Packaging and electronics are leading the way for machinery, partially offset by "continued automotive end market management," the company said.

Milacron did not make any announcement about its sales during NPE2018 in May, but Goeke said the Cincinnati-brand press that the company showed in Orlando, with 2,250 tons of clamping force, marked its return to large-tonnage automotive presses.

Goeke said orders for the new Cincinnati line are going well. "As we get further along Q3 and Q4, you get more competitive [on pricing] to make up orders," he said.

"The biggest selling point of equipment is not really cost structure but performance," Goeke said.

Chief Financial Officer Bruce Chalmers gave an update on the shutdown of Milacron's Ferromatik injection press factory in Malterdingen, Germany, as the assembly is being relocated to other operations. The plant is working off a backlog and should ship its final machines in the fourth quarter, he said. Milacron will have a large severance package in that last quarter, he added.

Sales of the Melt Delivery & Control Systems segment, which includes hot runners, coinjection molding systems, mold bases and components, and process control systems, generated sales of $124.1 million in the second quarter, an increase of 9.4 percent from the year-ago period.

Sales to China and Europe primarily have driven the growth, the company said. Electronics and medical are among the strong end markets for the segment.