Business & people

Victrex preparing for Brexit

작성자 : Aeyoung Park

2018-11-07 |

조회 : 4484

▲ An Aprtiv film e-motor insulation from Victrex at Fakuma 2018. (ⓒCaroline Seidel)

As the only maker of polyetherethe ketone in Europe, Victrex plc is closely following Brexit, the United Kingdom's departure from the European Union set for March 29.

The Lancashire, England-based specialty chemical company has set up a Brexit steering team to assess all the risks and opportunities associated with the exit, according to CEO Jakob Sigurdsson.

"Like many U.K.-based export companies, the key challenge we have identified is around the distribution of goods through ports into Europe," he said in an interview at Fakuma 2018.

Victrex already has subsidiary companies in Europe, including Victrex Europa GmbH, and it is securing additional warehousing in Europe to hold a higher level of stock, should there be a need.

At Fakuma, the company is showcasing new grades for food contact, as well as a novel solution for electric motors and gears for electric vehicles.

The company is also presenting its 150-micron PEEK polymer-based Aptiv film as an alternative for slot liner insulators in thermal management of electric motors, which are increasingly used with the rise of e-mobility.

Victrex has carried out simulations for replacing a 250-micron meta-aramid-PET-laminate slot liner material with Aptiv film and the results indicated that the film, which is 40 percent thinner, could improve heat flow in permanent magnet synchronous machine (PMSM) motors.

Since PMSM is designed to cut off at temperatures that threaten to damage its internal insulation, thermal management is a crucial performance factor for motors in electric vehicles.

Furthermore, Victrex is displaying polyaryletherketone-based composites for the aerospace industry as well as other materials for household appliances during the Fakuma show.

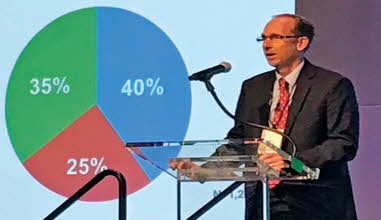

According to Sigurdsson, Victrex sees growth potential in all of its markets, which include automotive, medical, electronics and food and beverage.

"With our new food-grade product portfolio, we see increasing potential, with the food-processing market growing at around twice as much as industrial growth," he said.

In the automotive industry, Victrex is aiming to grow the PEEK content per car from 8 grams to 12 grams in coming years, with a long-term potential for more than 100 grams in electric vehicles.

Applications for PEEK currently include braking systems, and recently developed PEEK gears have just hit the road. With growing demand for EVs, the company is focusing on electrical insulation.

| ▲ Sigurdsson (ⓒVictrex plc) |

While currently capable of addressing demand, Sigurdsson has an eye on expansion of operations in anticipation of future growth.

"We're currently exploring options for new polymer production capacity in terms of location and size. However, at this stage, no investments have yet been made," he added.

The company sees itself needing new capacity in about five years to be able to meet growing demand in the next decade.

Victrex has also invested in an aerospace joint venture in Rhode Island to provide PAEK composite solutions to the industry.

TxV Aero Composites will offer a range of solutions such as custom laminates, preformed composite inserts for hybrid molding processes, along with finished composite parts and complete overmolded composite components and assemblies.

"With TxV, we have established a technology platform, which enables a fast and broad adoption of PAEK-based composite components in collaboration with OEMs and their global supply chain," Sigurdsson said.

The company is also advancing its materials expertise in 3D printing in collaboration with the U.K.'s University Exeter. The partnership, announced last month, aims to develop next-generation PAEK for additive manufacturing.

"PAEK is widely regarded as one of the highest-performing thermoplastics in the world. It offers a whole set of attractive properties for applications in demanding environments," Sigurdsson noted.

PAEK materials in development in this project have reduced processing temperatures compared with other members of the PAEK family while retaining high levels of crystallinity.

The company is currently conducting precommercialization tests for its materials, which have been developed for various 3D printing technologies, including laser sintering and fused filament fabrication.