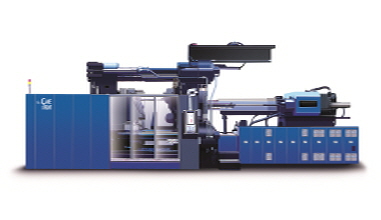

'Enjoy Innovation' with Wittmann Battenfeld at upcoming K 2019The Austrian machine manufacturer will present a series of Industry 4.0 solutions▲Wittmann Battenfeld An Eco Power injection moulding machine from Wittmann BattenfeldMachine and automation manufacturerWittmann Battenfeld has released details covering which systems it plans todemonstrate at the upcoming K Show 2019.The K fair will be held at MesseDusseldorf, October 16-23.Under the banner "EnjoyInnovation," the machine maker will showcase intelligent machinesusing adaptive algorithms which have the capability to adjust themselvesaccording to the ambient conditions.As part of this, an all-electricEcoPower 55/350 equipped with the HiQ-Flow, HiQMelt and HiQ-Metering softwarepackages will be available for demonstrations.This set up will producepolycarbonate clothes pegs using a four-cavity mold supplied by Austriantooling specialist Lechner.These systems, plus all auxiliarycomponents, will be integrated into the machine’s Unilog B8 control system viaWittmann 4.0.With this suite of hardware andsoftware, the system will be able to check whether the connected auxiliariesare sufficient to support the selected product data set, or if additionalequipment is needed.Additionally, the cell can compensateautomatically for material viscosity fluctuations, supporting stable output andhelping to eliminate scrap.Wittmann notes that bad parts will bedeliberately produced in order to demonstrate the company’s Max 9 granulator,also present on the stand.This and a series of other WittmannBattenfeld demonstrations will be available at Hall 15, stand C06.source : https://www.plasticsnews.com/news/enjoy-innovation-wittmann-battenfeld-upcoming-k-2019

editor

2019-09-22