Chemical reports

How glass fiber compounds improve cost-effectiveness

작성자 : Ms. Park

2017-11-24 |

조회 : 1216

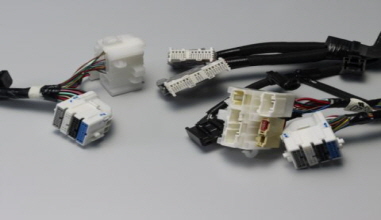

Lightweight design, including the use of robust yet lightweight materials, has become an imperative in manufacturing, particularly in the automotive industry. Light-weighting helps reduce vehicular CO2 emissions and thus plays a crucial role in enabling manufacturers to adhere to regulatory standards.

New level of processability and physical properties

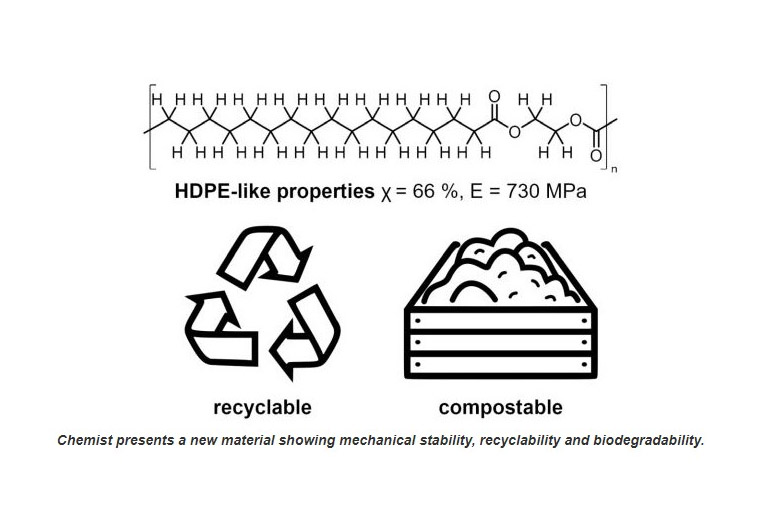

| ▲ Tensile strength comparison of Cremaid and other PA compounds. |

A new family of compounds from Teknor Apex Company raises the processability and physical properties of glass fiber reinforced polyamide (PA) to a new level, enabling injection molders to take on more demanding metal-replacement applications or replace alternative thermoplastic materials for greater versatility in processing.

New Creamid compounds exhibit higher tensile strength and better flow properties compared with standard glass-filled polyamide counterparts, greater dimensional stability, lower water absorption, improved chemical resistance, and enhanced surface aesthetics, according to the US company.

In metal-replacement applications, Creamid compounds are frequently formulated for a flexural modulus as high as 21GPa, giving molded parts high dimensional stability. These grades also provide tensile strength up to 260MPa, a property more commonly expected from die-cast aluminum or zinc, and offer significant savings in part weight.

When combined with longer tooling life and lower material cost, metal-replacement projects with Creamid polyamides typically produce very high returns on investment for OEMs, according to Brian Rickard, Director of Strategy and Business Development for the Engineering Thermoplastics (ETP) Division of Teknor Apex. The compounds have been successfully used in Europe for automotive air vents, spoilers, fan blades, spring adapters, and key fobs.

The processing advantages are also dramatic compared with standard glass-filled PA. For instance, versus a standard 43% glass-filled PA, a 40% glass-filled Creamid compound shows a 68% improvement in spiral flow tests, reaches a 41% lower peak injection pressure, and requires 43% less clamp force.

Longer flow length and lower injection pressure translate into a wider processing window, more efficient filling of complex or thin-wall cavities, reduced part warpage, and a possible reduction in the number of gates or knit lines. A lower clamp force also opens the possibility of increasing the number of cavities or running parts in a smaller, less costly molding press.

EV brings new opportunities

The emergency of electric vehicle (EV) also fueled the demand for lightweight design that improves the driving range. What’s more, an exciting new gamut of design possibilities can be realized. For example, components in battery electric and fuel cell electric vehicles can be fundamentally redesigned for low density polypropylene (PP) compounds due to lower operating temperatures versus internal combustion engine (ICE) powertrains.

Components such as tailgates and front end modules can be executed in monomaterial PP solutions that are not only lighter weight, but are more easily recycled. And where metal and higher-cost engineering plastics were once the material of choice for structural elements, PP-based compounds can now be considered for such applications.

At the VDI International Plastics in Automotive Engineering Conference in March, polyolefins specialists Borealis and Borouge launched two new grades in the Fibremod range of PP fiber reinforced compounds for interior, exterior, and under- the-bonnet (UTB) automotive parts.

The proprietary Fibreod long glass fiber reinforced PP (LGFPP) is known for its good fiber impregnation and

flexibility in allowing for use of various PP matrices, and

the production of grades in customized colors, said Borealis.

One of the new grades is LGF Fibremod GB416LF with 40% filler content, offering a new solution for a full polyolefin tailgate module as a lower-density replacement solution for conventional metal or engineering polymers.

As a high-flow material, Fibremod GB416LF fulfills both emission requirements and mechanical performance criteria. With high quality surface aesthetics, the grade can be used for visible parts. Its sustainability is enhanced not only by its lighter weight, but by eliminating the need for one or more paint layers, or additional aesthetic parts, explained the company.

Another new offering, Fibremod GD577SF, is a short glass fiber grade with 50% filler. Apart from strong mechanical properties, the grade provides pleasing surface quality for visible structural parts.

As a potential replacement solution for demanding metal and PA applications, GD577SF is suited for a diverse range of exterior, interior and UTB applications, including full plastic front end modules, clutch and gas pedals, external mirror structures, etc.

Maximum safety for E&E

Safety, in particular fire resistance, is of paramount in E&E applications. Miniaturization of electronics parts places tougher requirements on the material used. Lanxess responded to this trend by introducing two new Durethan flame-retardant PA 6 compounds that are highly reinforced with glass fibers.

Marked specimens of the new, halogen-free, flame-retardant polyamide Durethan BKV45FN04 are clamped in a tensile testing machine.They are ideal for components subject to high mechanical load, such as structural parts in industrial machines that must meet flame retardance requirements, and molded case circuit breakers (MCCB).

“In addition, they are a substitute for die-cast metals and thermosets, when the high stiffness of these materials is not needed,” said Alexander Radeck, Applications Development Expert in the High Performance Materials (HPM) business unit. “Processors benefit from the high design freedom and cost-efficiency afforded by injection molding.”

The first grade, Durethan BKV 45 FN04 is reinforced with

45%-by-weight short glass fibers. Its flame retardance

package contains no halogens or red phosphorus. The

high-modulus material can therefore also be colored as

desired.

The material passed the UL 94 test of the US testing

organization Underwriter Laboratories (UL), achieving the

best classification of V-0 with test specimens just 0.4mm

thick.

“In the even tougher UL 94-5V test, the compound achieves the best rating of 5VA at just 1.0mm, and that’s entered

accordingly on the UL Yellow Card,” continued Radeck.

With a CTI A (Comparative Tracking Index, IEC 60112) of 600 volts, the material is highly tracking resistant. Electronic assemblies can therefore be positioned closer together without resulting in shorts or device defects caused by leakage current.

Another of the material’s strengths is its high-voltage tracking resistance to DIN EN 60587 and ASTM D2303 (Inclined Plane Tracking, IPT). The test recreates how strongly the insulating capacity of a surface changes at high voltages outdoors when exposed to moisture and soiling.

“The Yellow Card lists a good IPT voltage for our material of 1 kilovolt at 60 minutes tracking time. That means it’s also suitable for components used in high-voltage battery systems in electric cars,” explained Radeck.

The second new compound from Lanxess is on the verge of market introduction and contains over 50% glass fibers. With a halogen-based flame retardance package, it likewise achieves V-0 (0.75mm) and 5VA classification in UL 94 testing (UL Yellow Card).

The high flame retardance is also evident in glow wire testing to IEC 60695-2-12/13. For example, at 775°C, the product easily fulfills glow wire ignition temperature (GWIT) requirements.

“With these results, the material is destined for components subject to high mechanical stress, such as in household appliances (IEC 60335-1). It also has great opportunities for use in housing parts and covers of circuit breakers,” said Radeck. The compound’s CTI A tracking resistance is high at 575°C (PLC 0 on UL Yellow Card).

With their high glass fiber content, both of the new engineering materials display unusually high stiffness and strength. Durethan BKV45FN04, for instance, has a tensile modulus of 16,000 megapascals (freshly molded).

Despite glass fiber reinforcement, the melts of both thermoplastics display high flow properties thanks to EasyFlow technology, according to Lanxess. “Components can therefore be designed with thin walls, complex geometries and relatively long flow paths,” said Radeck.

China Plastic & Rubber Journal (CPRJ) - Oct 2017 Issue

Source: China Plastic & Rubber Journal By Victor Cheng