Chemical reports

BASF pushes lightweighting solutions to suppliers, automakers

작성자 : Aeyoung Park

2018-02-02 |

조회 : 4151

BASF pushes lightweighting solutions to suppliers, automakers

flooring systems.

BASF Corp. was showing off flooring material for vehicles that it called a lightweight, low-cost solution for automakers.

BASF supplied the chemistry for the piece, which is manufactured by German supplier Koller

Beteiligungs GmbH.

"It's a lightweight, low-cost solution for automotive applications for any type of load floor or

hatchback or sunshade type applications," said Jeffrey Hagar, market segment manager for

BASF.

Hagar said the part is corrugated honeycomb composite sandwiched between non-woven fiberglass.

"We then spray the polyurethane on both sides of it, and it gets compressed into a tool to

come out with this geometry and this semistructural part," he said.

Traditionally, the part has been made out of blow molded polypropylene. Hagar said the new

part is about a 50 percent weight savings.

"In addition to the significant weight savings, there are advantages to adhering carpet to

polyurethane. You have to do some additional processing to attach to polypropylene. You are getting a much better bond between the carpet and the substrate," Hagar said.

The part was one of several that BASF showed off at the North American International Auto

Show in Detroit.

The company also discussed a collaboration with IAC Group for a lightweight instrument panel foam with a cross-sectional thickness of as low as 4 millimeters.

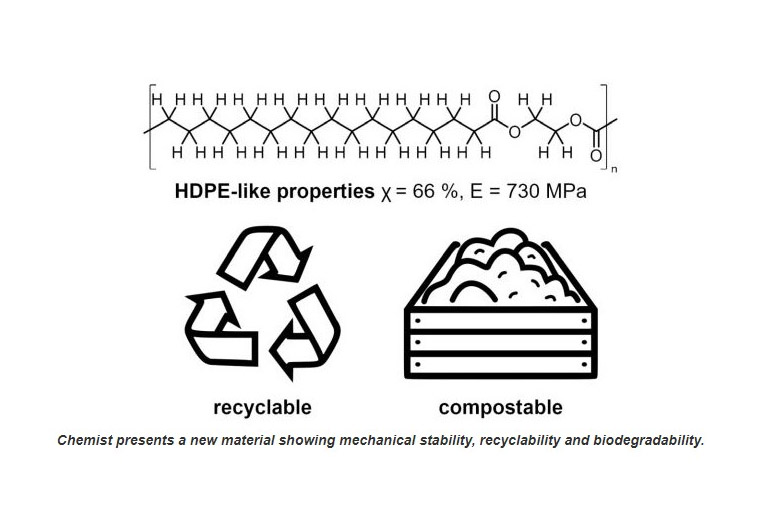

The piece has significant weight savings and cost reductions and it has bio-based content in

it, Hagar said.

"We have a green, sustainable solution, whereas instead of having more petrochemicals going into the marketplace, we're actually replacing this with castor oil, which is renewable and sustainable," he said.

The new instrumental panel saves about 40 percent compared to the traditional instrument

panel and is just as strong as the traditional material, Hagar said.

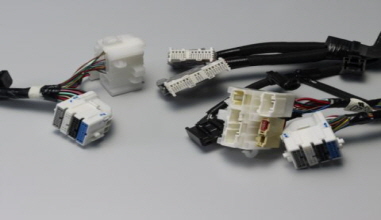

The company also showed off a strut mount off of a Cadillac CT6 where plastics replaced the

traditional steel and aluminum solutions. It is made by ContiTech Vibration Control.

BASF also showed off a clevis bracket for SUV and truck models with General Motors Co. The piece supports the engine and is made by Hutchinson Antivibration Systems.